Material :

AlloyPackage :

BagWarranty :

1 yearFeature :

Excellent Welding PerformanceQuantity :

High quantityFunction :

connectionUsage :

weldingLead time :

To be negotiatedUse :

weldingMOQ :

1 ton| Slag-forming gas shielded flux-cored wire | CO2 gas shielded flux-cored welding wire, the main varieties are used for carbon steel, 50 kg low alloy structural steel (all-position welding), high strength steel, low temperature steel, heat-resistant steel (1.25Cr-0.5Mo series, 2.25Cr-1Mo series), weathering steel (painted and non-painted), stainless steel (welded SUS304, 304L, 316, 316L, 317, 317L, 321, 347, 309S stainless steel), wear-resistant surfacing (Hv250, Hv350, Hv450, Hv600). |

| Ar-rich mixed gas shielded flux-cored welding wire, mainly used for carbon steel, 50kg low-alloy structural steel (all-position welding), high-strength steel (60-70kg), low temperature steel (-45°C, -60°C impact toughness), wear-resistant surfacing (13Cr-2Ni series). | |

| Metal powder cored flux cored wire | CO2 gas shielded flux-cored welding wire, the main varieties are used for carbon steel, 50kg low alloy structural steel, high strength steel (60kg), wear-resistant surfacing (high Cr-Fe series, Hv800) |

| Ar-rich mixed gas shielded flux-cored welding wire, mainly used for carbon steel, 50kg low alloy structural steel, low temperature steel (-60℃ impact toughness), stainless steel (13Cr-5Ni series, 13Cr-4Ni-Mo series, 17Cr series), wear-resistant surfacing (13Mn series, 16Mn-16Cr series). |

|

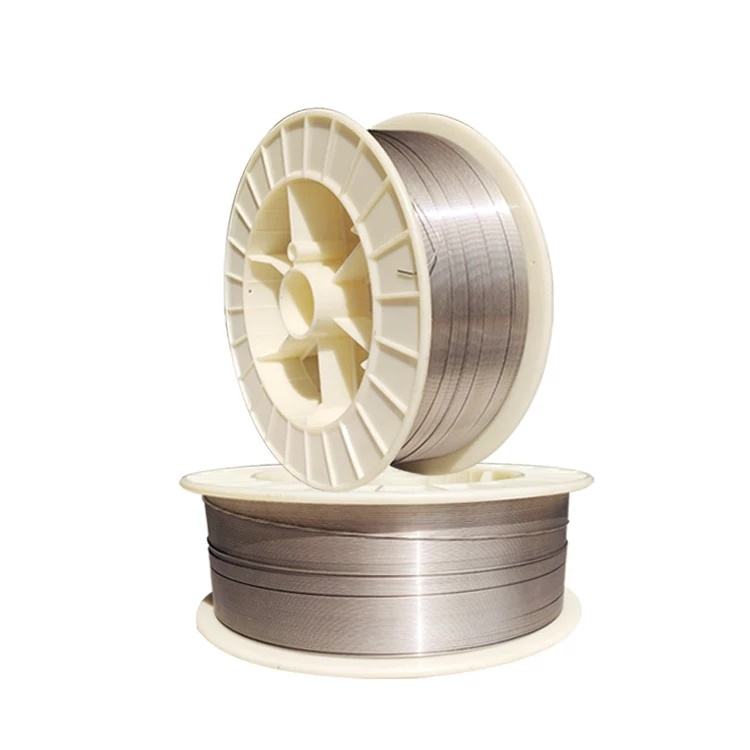

Flux Cored Welding Wire

|

|

| Type | AWS |

| Mig flux cored wire | AWS A5.29/5.28 E71T1-C(M), E81T1-K2, E81T1-NI1,E91T1-K2, E101-K3, E111T1-K3,E80C-G, E90C-G, E110CG |

| TIG Welding Filler Wire | ER70S-4, |

| Submerged arc surfacing flux cored wire | AWS A5.23 F71A, F8A4, F9A4, F11-A8 |

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)