Using coil nails in construction projects can significantly enhance efficiency and durability. However, even experienced builders can make mistakes that compromise the quality of their work. In this blog post, we’ll highlight some common mistakes to avoid when using coil nails for construction, ensuring your projects are both successful and long-lasting.

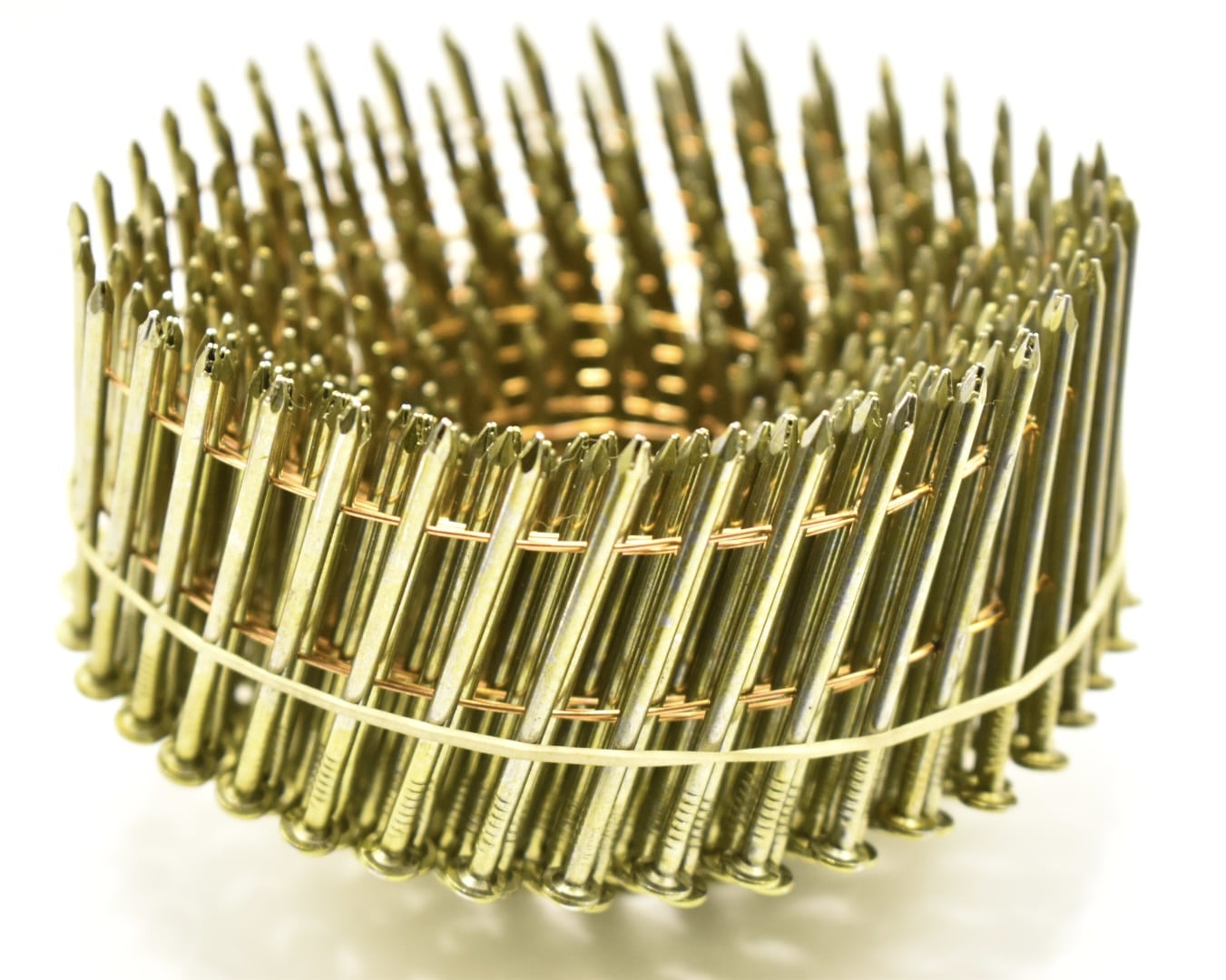

One of the most common mistakes is selecting the wrong type of coil nail for the job. Coil nails come in various types, including galvanized, stainless steel, and copper. Each type is suited for different applications and environments. For example, galvanized coil nails are ideal for outdoor projects due to their corrosion resistance, while stainless steel nails are perfect for areas exposed to moisture. Always choose the right type of coil nail to match your specific construction needs.

Using the wrong length and gauge of coil nails can lead to structural issues. Nails that are too short may not provide adequate holding power, while nails that are too long can split the material. Similarly, using the wrong gauge can affect the nail’s strength and durability. For most construction projects, nails that are 1 1/4 to 2 inches long and have a gauge of 0.120 to 0.131 are typically the best choice. Always ensure you’re using the correct specifications for your project.

Another common mistake is not adjusting the nail gun settings properly. Incorrect pressure settings can cause nails to be driven too deep or not deep enough, leading to weak joints or surface damage. Always refer to the manufacturer’s guidelines for the correct settings and test on a scrap piece of material before starting your project.

Safety should always be a top priority when using coil nails in construction. Failing to wear appropriate safety gear, such as safety glasses and gloves, can lead to serious injuries. Additionally, always ensure your work area is clear of obstructions and that you’re using the nail gun correctly. Following safety protocols can prevent accidents and ensure a smooth construction process.

Environmental factors, such as humidity and temperature, can affect the performance of coil nails. For instance, using non-galvanized nails in a humid environment can lead to rust and corrosion, compromising the integrity of your project. Always consider the environmental conditions and choose coil nails that are designed to withstand them.

At Hongfeng Metalware, we offer a selection of high-quality coil nails that meet the demands of various construction projects. Our coil nails are crafted with precision and high-grade materials, ensuring exceptional durability and corrosion resistance. Whether you need galvanized steel, stainless steel, or copper coil nails, we have the perfect solution for your construction needs.

Our coil nails offer:

Superior Holding Power: With ring shank designs, our nails provide a strong grip, preventing loosening over time.

Corrosion Resistance: Our hot-dipped galvanized and stainless steel nails are built to withstand harsh weather conditions.

Versatility: Suitable for various construction materials and compatible with most nail guns, our coil nails ensure efficient and reliable performance.

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)